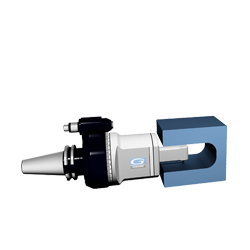

Angle Heads Evolution Line

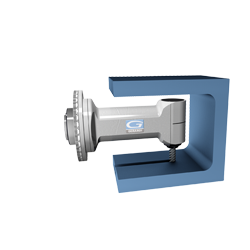

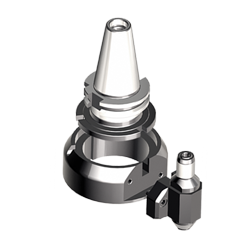

Modular angle heads

The new Evolution line of Gerardi angle heads has been designed from a technical base derived from 40 years experience of solving thousands of production problems, finding optimum solutions and always guaranteeing the highest product quality. More than 96 standard angle head types are now offered, designed, built and distributed in more than 50 countries the world over by Gerardi S.p.A., and available with a range of options to complete their applications and performance potentials.

The Compact design, along with mentioned specifications, allows: highest performances, high speeds, long tools life.

Identify your Angle Head with our worksheet

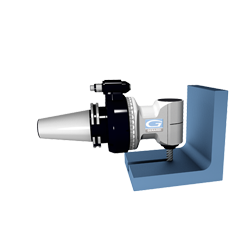

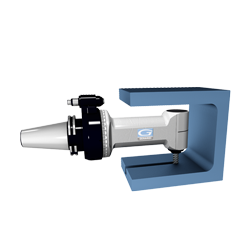

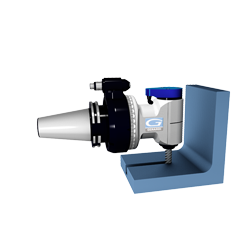

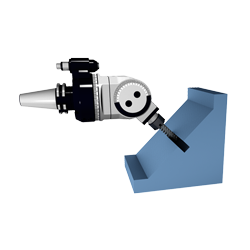

ATC series

ATC angle heads are ideal for CNC machines with automatic tool change and can be automatically transferred from the tool store to the machine spindle and vice-versa.

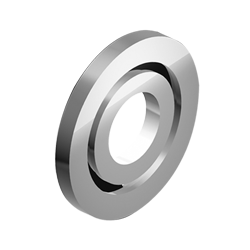

The orientation ring and arrester arm support ring are both 360° adjustable to allow the best angular orientation. On FMU heads, the cutter spindle housing can be adjusted at ±90°.

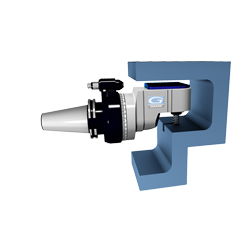

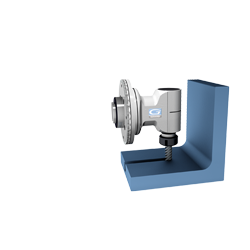

MTC series

This range of angle heads is for conventional machines without automatic tool change.

MTC angle heads (Manual Tool Change) are manually mounted on the machine headstock through a flange.

On FMU heads, the cutter spindle housing can be adjusted at ±90°.