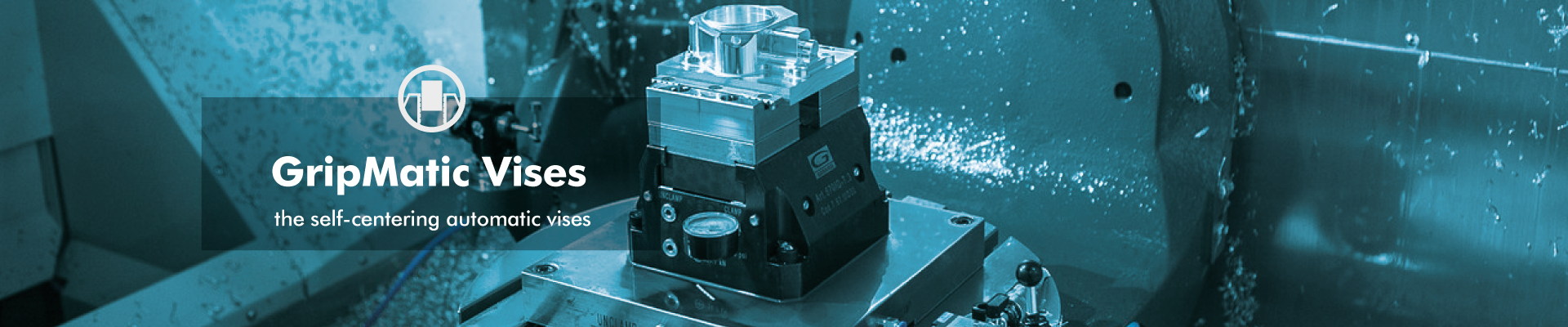

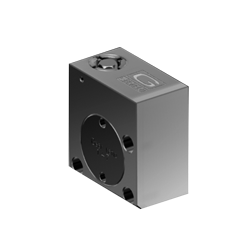

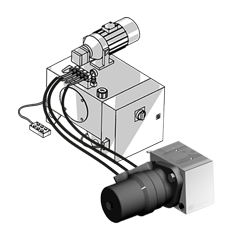

FMS VISES

The most complete vise. For single, double and self-centering clamping.

Born to be dedicated to machining centres, FMS series of vises allow workholdings with perfect alignment in a space saving design, extremely high wear resistence, with deflection reduced 2 times in respect to the STD modular vises (base thickness doubled), possibility to clamp more pieces simultaneously with mechanic, hydraulic pneumatic or electric devices. You can use them both for vertical and horizontal clamping without any price charge. Jaws widhts from 75 to 190 mm. Grip any work lenght.

The feature (Pathented) which better identifies this line of vises consists in the possibility to trasform each single vise (1 piece clamping) in a self-centering vise with possibility to block from outside to inside and viceversa and in a double vise through the simple substitution of the jaws on the universal vise body base. A simple and quick adjustment will then allow following clamping alternatives: single long piece, 2 smaller pieces or to operate in the self-centering way.

All that suggests their use in the production of lots of highly different pieces reducing set-up times and assuring very accurate repeatability of workpiece position and precision, increasing the global efficiency of the production process.