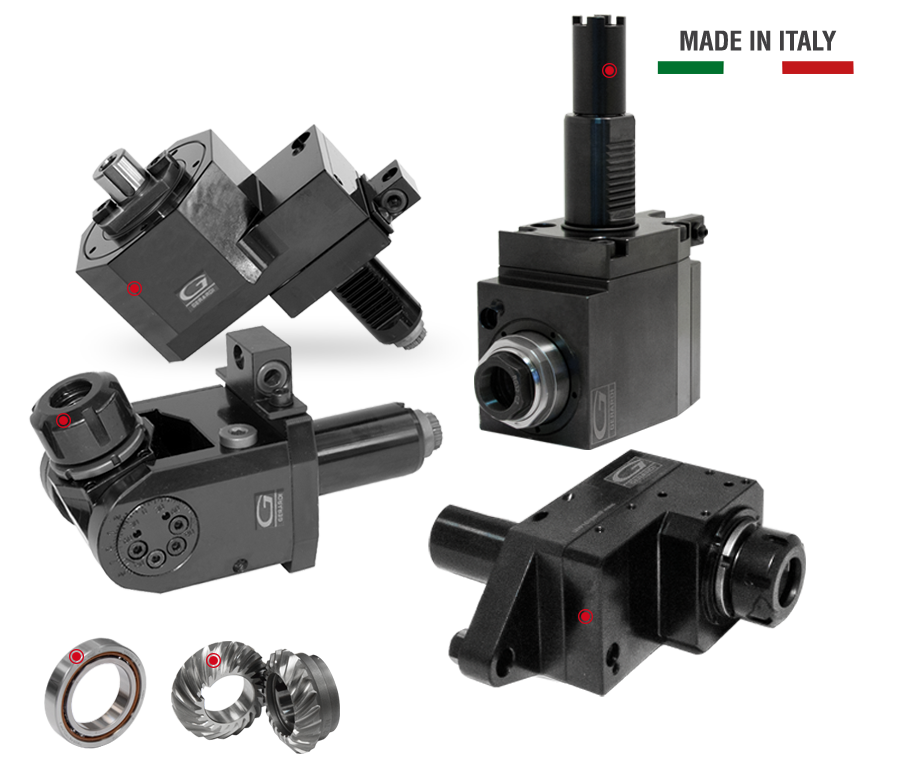

MAIN BODY

Re-designed main body to improve rigidity and reduce vibration.

Specially treated corrosion resistant steel body

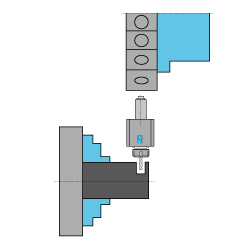

INTERNAL COOLANT

All the driven tools, can be supplied with coolant feed through the spindle with rotating distributor up to 70bar

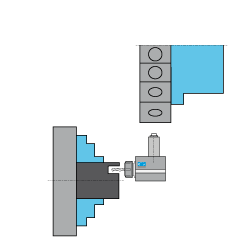

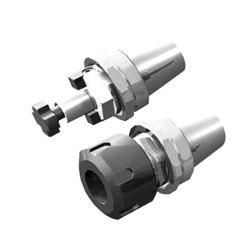

COUPLING

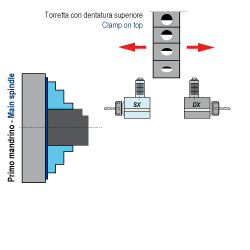

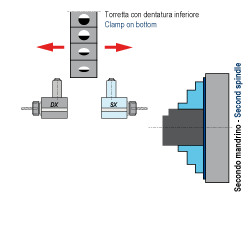

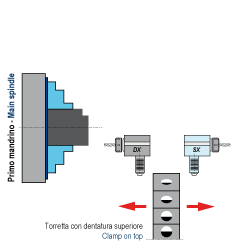

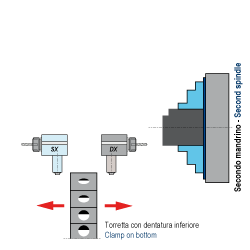

Interchangeable couplings for the different Haas turret

GLEASON GEARS

Gleason computer based calculations for the Gleason cut spiral bevel drive gears with ground teeth in order to guarantee a bigger torque.

BEARINGS

Angular contact preloaded ball bearings of precision class ABEC 9.

100% MADE IN ITALY

OPTIONS

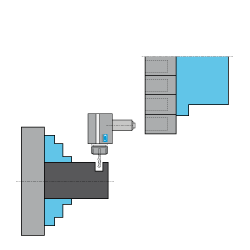

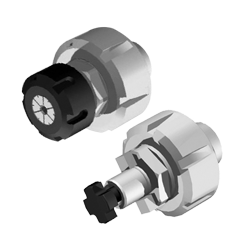

HIGH SPEED

There is also the possibility of speed increaser from 2 to 4 times thus adapting the Rpm of the turret drive to the speed of today's cutting tools. The epicyclic speed increaser system (a system of satellite gears) is self contained in the standard head overall dimensions and guarantees the same standards of quality and reliability.

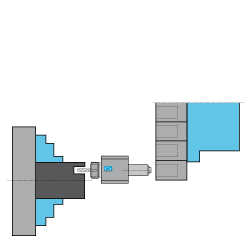

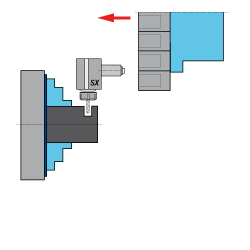

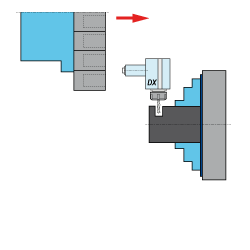

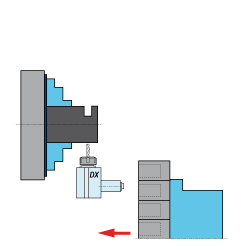

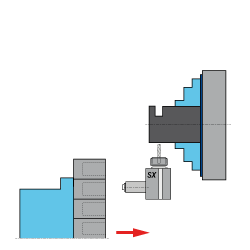

MULTIPLE OUTPUTS

All the driven tools, with the exception of those with adjustable angle, can be supplied with double or multiple output even of the same dimension. Multiple outputs can be opposite or with the same direction.

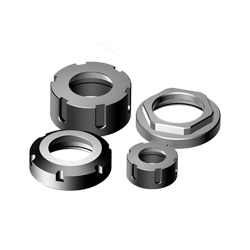

TAPPING

For tapping operations all driven tools can be equipped with axially compensated collets ET-1 interchangeble with the standard ER collets according the international standard DIN 6499.They allow the tap an axial compensation from 7 to 13 mm according to their size in order to compensate any feed error and the inversion of the rotation of direction.